Understanding Sail Tensioning

Before Alado Roller Furling came along, some die hard racing sailors would lessen the jib halyard tension to reduce the useable surface area of the sails.

That was fine with "hank on" sails.

The purpose of Roller Furling is to be able "Roll in" the sail to any horizontal distance without adjusting the vertical tension.

Loosening the halyard tension will only cause wrinkles in the sail and overlap, which, when furled up, may cause damage to the sail or foils.

Basic Operating Principle of the Alado Halyard

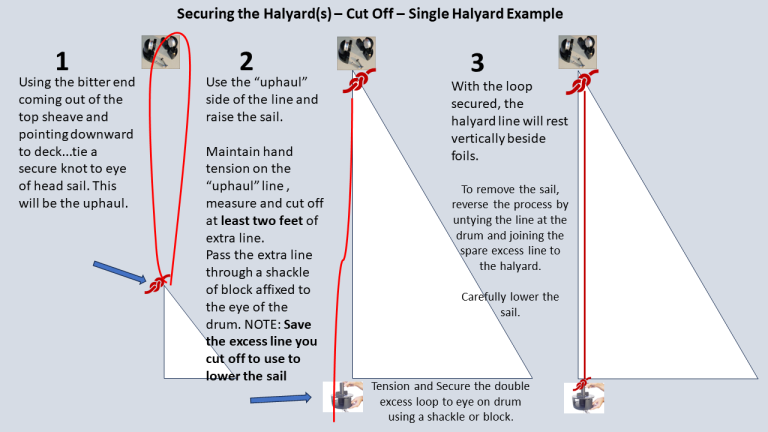

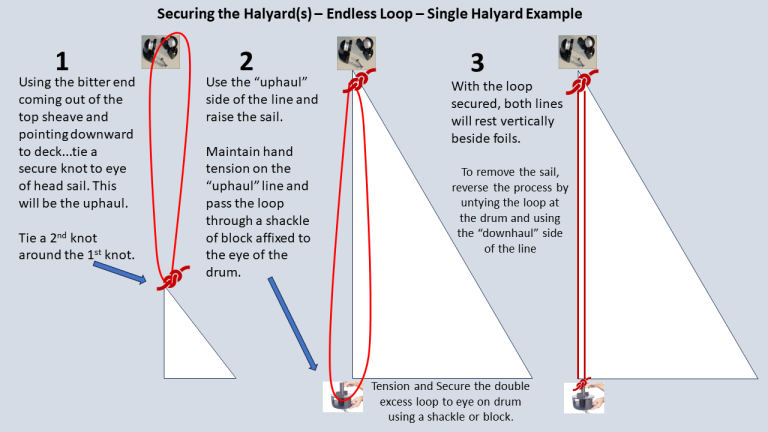

The sail is lifted by the mechanical action of a 1:1 lift using the uphaul line of the external halyard you install. For every foot lifted an equal foot of line is required.

The head of the sail should stop just a few inches below the sheaves to allow full tensioning ability. If not, satisfactory tension may not occur.

TIP: Installing the System then measuring the "luff" distance before you cut or order a sail will ensure no " size surprises" when you install the sail.

Once sail tension is achieved, secure the "downhaul" line of the external halyard by tying it off or alternately you can attach a turnbuckle to the drum and an eye splice on your new halyard for easy attaching.

It is not recommended to drill any holes in the drum as this may crack the casting and void the Lifetime Warranty.

The Physics Explained...

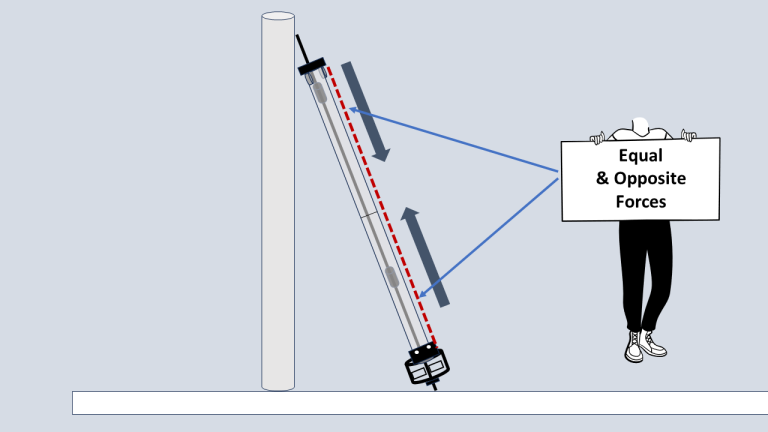

- With the tack of the sail secured to the Drum, the luff of the sail is in essence now part of the uphaul and is adding "upward force" to the drum when the external halyard runs through the Top Sheave.

- Tensioning and securing the "downhaul" line to the drum creates an equal "downward force". The system now has equal & opposite forces at work, keeping the Top and Drum extra secure by use of vertical pressure on the interlocked foils.

TIP:

The use of a high-quality low stretch rope for the external halyard will mitigate any accidental loosening of the sail.